QLC Considerations for Mainstream Adoption

How QLC SSDs can lower costs and improve outcomes for broader data center storage

In response to the ever-increasing demand for data storage, characterized by exponential growth and the necessity for more economical and higher-density storage solutions, flash technology has progressed from 2D to 3D architecture, from tens of layers to several hundred, and from SLC and MLC to TLC and QLC.

As of now, 3D TLC NAND stands as the predominant flash NAND technology, while 3D QLC NAND is steadily gaining traction as it evolves and garners greater acceptance from consumers and an expanding ecosystem. QLC-based SSDs offer better environmental sustainability, scalability, cost-effectiveness, and storage capacity when compared to available alternatives in the market.

This article delves into the reasons behind the continued growth in demand for QLC technology and provides a comprehensive comparison of QLC SSDs with established storage device options. This comparison is intended to equip data center architects with the knowledge required to make optimal choices for their storage needs. Before we embark on the exploration of QLC's readiness for mainstream acceptance, we will commence with a brief overview of QLC definitions and industry standards.

What is QLC

QLC stands for quad-level cell where each NAND cell stores four bits of data. As the number indicates, this extra bit allows for higher density than triple-level cell (TLC), the most common NAND flash shipped today. That fourth bit translates to an instant increase in areal density along with cost savings, even without taking into account other cost savings at the SSD level, such as less DRAM with coarse IU. With this advantage, Solidigm 192L QLC areal density (18.6 Gb/mm sq) is much greater than comparable TLC NAND, even with fewer layers. [1]

To store four bits, the QLC cell needs to write and read 16 voltage levels, twice that of TLC, which does lead to a relatively lower program/erase (P/E) cycle and input/output (I/O) speed than TLC at the NAND level.

However, SSD performance and endurance are influenced by a multitude of factors at the drive level. These encompass the I/O interface speed, firmware optimization and tuning, overprovisioning, as well as controller and channel configurations, all of which complement the inherent characteristics of NAND component alone.

Likewise, beyond the NAND component itself, the quality and reliability of SSDs are heavily reliant on the operational environment, the overall resilience and integrity of firmware and hardware across a diverse range of applications, the precision of the manufacturing process, and the effectiveness of data protection mechanisms.

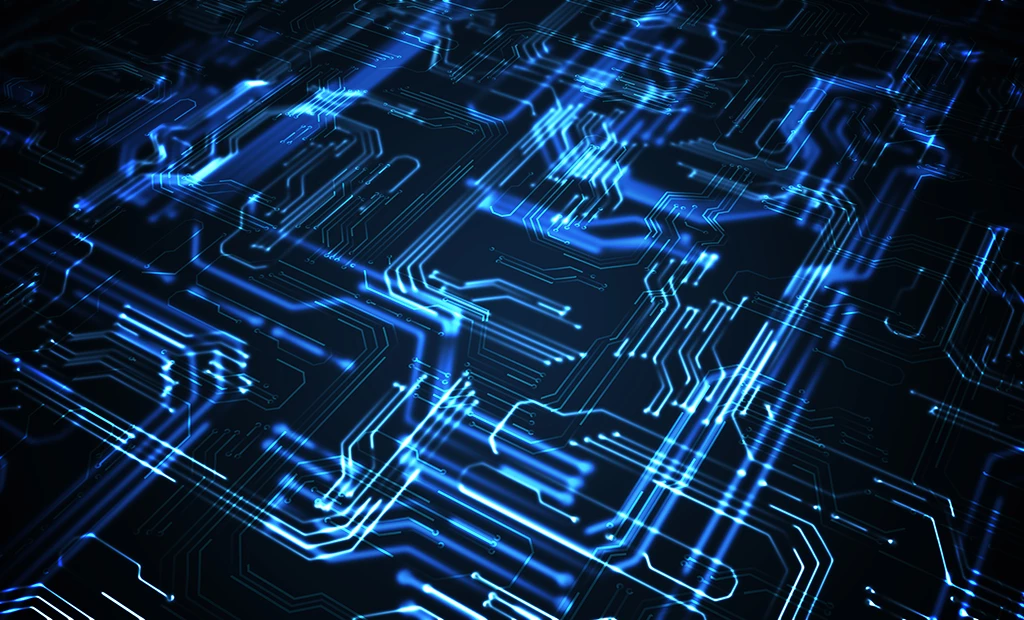

Solidigm QLC NAND technology has evolved through four generations of development since its inception in 2017, leading to substantial improvements in terms of endurance, performance, and storage density.

Figure 1. Solidigm QLC NAND evolution

In the upcoming sections of this article, we will utilize Solidigm D5-P5336 and D5-P5430 as an example to showcase the total cost of ownership (TCO) and performance that QLC drives can attain.

How is QLC ready for broader adoption

As we analyze QLC’s readiness for broader adoption, we will focus on four key aspects: vendor readiness, data access pattern alignment, ecosystem, and cost. Let’s take a look at each of these now.

Vendor readiness

Leading NAND and SSD manufacturers have already commenced mass production of QLC-based NAND and QLC SSDs for both client and enterprise. Notably, Forward Insights has forecasted that QLC's market share will grow to 30% by 2025. [2] As a prime example, Solidigm has already advanced to its fourth generation of datacenter QLC SSDs. The latest generation of Solidigm QLC series D5-P5336 exhibits an impressive petabytes written (PBW) of up to 213 PBW on sequential write and 65 PBW on random write which translates to 0.58 random drive writes per day (DWPD). The persistent commitment to investment and ongoing enhancements of the QLC technology across the industry serves as the linchpin for its continued growth.

Data access pattern alignment

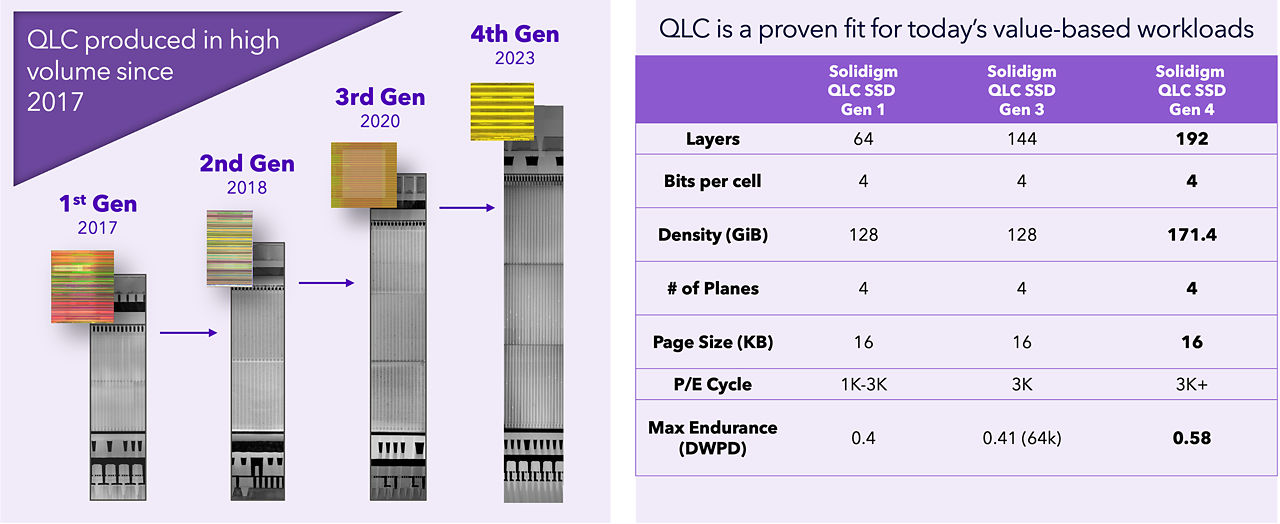

Figure 2. Data center workloads

In today's data centers, the predominant workloads consist of read-intensive operations with larger data transfer sizes. Storage architects place a greater emphasis on designing systems that facilitate quicker and more consistent data read access at a reduced cost. Concurrently, file systems and storage engines shape write IOs to optimize performance, effectively maximizing write bandwidth and prolonging the life of flash drives. Additionally, as drive capacity increases, the requirement for drive endurance, as indicated by the DWPD (drive writes per day) rating, decreases for the same Petabytes Written (PBW).

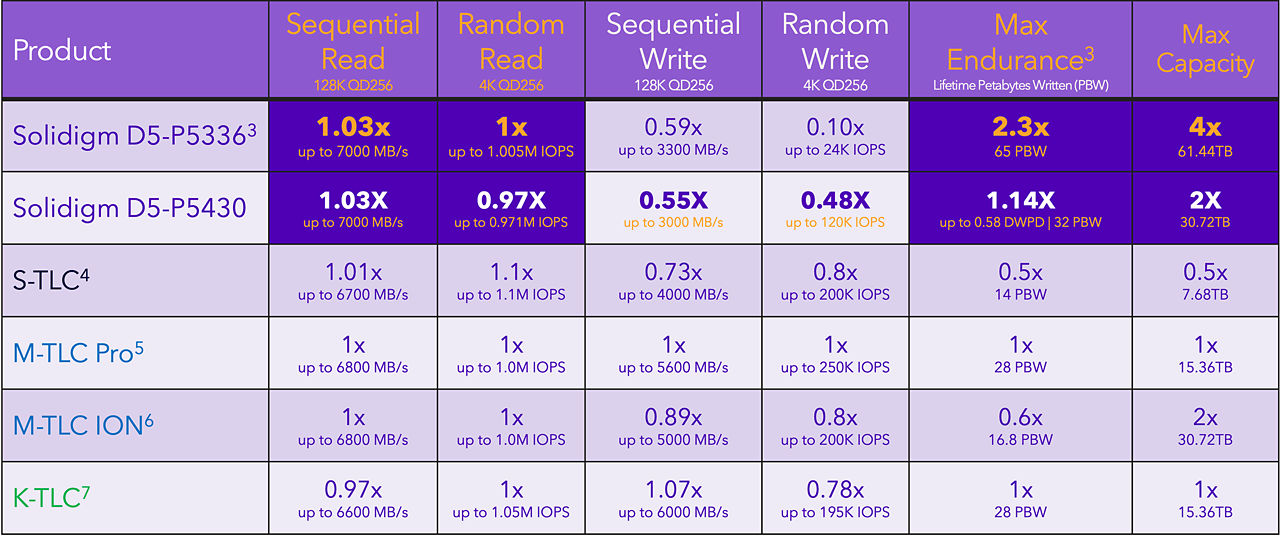

Table 1. QLC SSDs performance and endurance comparison to TLC SSDs

Backed by the performance of Solidigm D5-P5536 series, QLC-based flash drives prove to be a highly suitable choice for the modern data center, generating significant value for non-random-write-intensive use cases. It not only lowers OPEX (Operational Expenditure) but also elevates both IO/GB and IO/$ metrics compared to traditional SATA/SAS hard disk drives and slashes CAPEX (Capital Expenditure) costs when contrasted with TLC alternatives with minimal to no compromise in performance.

Ecosystem

Storage hardware and software providers have proactively developed solutions and services tailored to QLC technology. Companies like VAST Data, Dell Powerscale, Pure Storage, IBM, DDN, NetApp, and many others have integrated QLC-based applications into their offerings.

Moreover, numerous cloud service providers, including Alibaba, have already embraced QLC in services like Elastic Compute Service (ECS) for big data local disk instances. When QLC SSDs are deployed to replace short-stroked HDDs, it results in marked improvements across performance, capacity, latency, and the TCO. As the ecosystem continues to evolve, innovative use cases will emerge, attracting a wider group of adopters to follow suit.

Cost

With the accelerated decline in flash prices compared to HDDs, the gap between the price-per-gigabyte of HDDs and flash storage is rapidly narrowing. This ongoing trend is expected to accelerate the adoption of flash technology, particularly QLC flash, thanks to its exceptional total cost of ownership (TCO) benefits driven by its ultra-high areal density.

In support of this, a TCO analysis conducted by Wikibon Research has revealed substantial savings, amounting to $30.3 million, over a 10-year period for a 10PB QLC SSD based cluster, in comparison to traditional HDD solutions. [8]

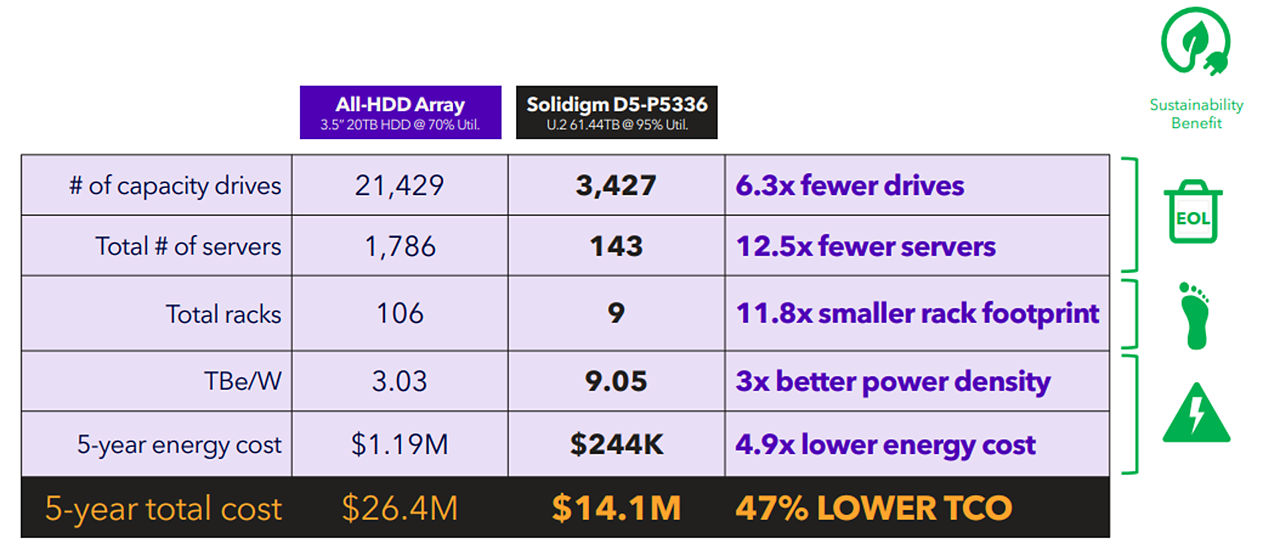

Table 2. TCO value when solving for 100PB object storage cluster

Table 2 presents a TCO cost-benefit analysis demonstrating an impressive 47% TCO saving when comparing QLC to HDD over a five-year span. These savings encompass reductions in rack space, energy consumption, labor costs, and the added advantage of a significantly reduced end-of-life disposal footprint, contributing to enhanced sustainability.

Solidigm is poised to bring QLC to the mainstream

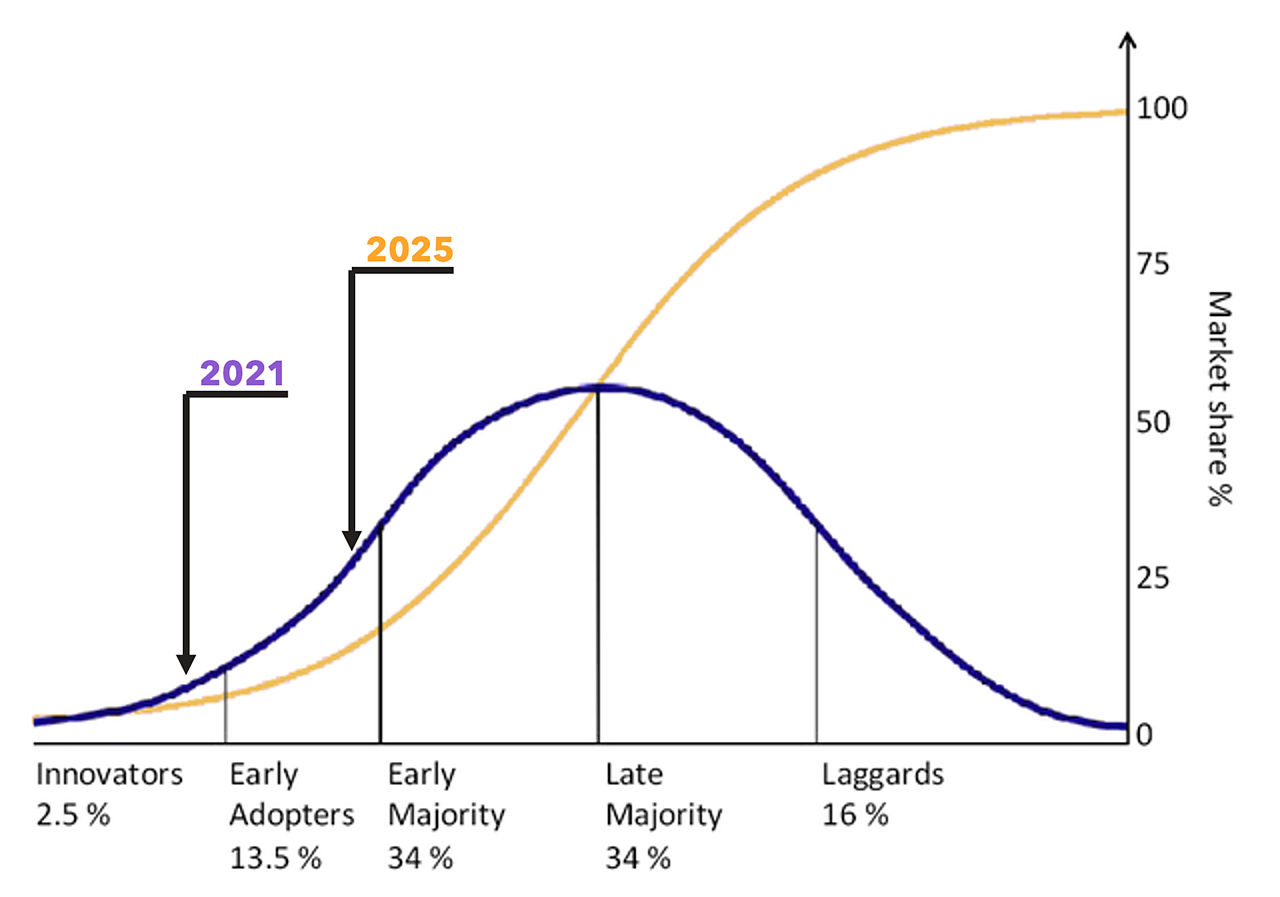

The innovation adoption lifecycle depicted in Figure 3 is known as the “Roger’s bell curve” by Everett M Rogers, author of Diffusion of Innovations. He divided adopters into five categories, and using this underlying understanding of the innovation lifecycle, we can plot data centers adopting QLC as part of their storage solutions along this curve. Based on Forward Insights’ estimation on QLC adoption rate, we expect to see a shift from innovators phase to early adopters and early majority by 2025.

Figure 3. Expansion of QLC market into mainstream

Solidigm, a pioneer and leader in QLC storage solutions, boasts the expertise and experience needed to build high-quality products that precisely align with end users' demands for reliability, endurance, and performance. After years of dedicated product refinement, Solidigm's data center QLC SSDs have demonstrated a remarkably low rolling Annual Failure Rate (AFR). [9]

QLC-based solutions are already making headway, displacing performance and nearline (NL) HDDs, as well as TLC-based SSDs in various applications such as active archives, large-scale NAS, software-defined scale-out storage, and cloud and virtual machine environments. Wider adoption is clearly on the horizon.

Final thoughts

While QLC by itself may not dominate the entire market, it is progressively strengthening its position in the mainstream. Some of the motivators include software and filesystem support on coarse IO blocks and complementary products such as SLC SSDs. Computational or acceleration software and hardware that boost the performance and elongate the endurance of QLC will also have an impact, as will the cost savings on QLC NAND production resulting from economies of scale.

Notes

[2] http://www.forward-insights.com/reportslist.html

[3] Solidigm. D5-P5336 product specifications and current 5 quarter roadmap. Max endurance for D5-P5336 based on 100% 16K RW @ 61.44TB capacity.

[4] Samsung. Performance and PBW from highest capacity drive available. https://image.semiconductor.samsung.com/resources/data-sheet/Samsung_SSD_PM9A3_Data_Sheet_Rev1.0.pdf

[5] Micron. Performance and PBW from highest capacity drive available. https://media-www.micron.com/-/media/client/global/documents/products/product-flyer/7450_nvme_ssd_product_brief.pdf

[6] Micron. Performance and PBW detailed at https://www.micron.com/products/ssd/product-lines/6500-ion

[7] Kioxia. Performance and PBW from highest capacity drive available. https://americas.kioxia.com/content/dam/kioxia/shared/business/ssd/data-center-ssd/asset/productbrief/dSSD-CD8-R-U2-product-brief.pdf

[8] http://wikibon.org/wiki/v/Calculating_Infrastructure_TCO_per_VM

[9] Solidigm QRE Team internal tracking

About the Author

Yuyang Sun, Senior Manager of Product Marketing at Solidigm, has over a decade of experience in SSD storage design, business planning, marketing, and strategy. Her day-to-day interactions with major industry players have allowed her to gain invaluable insights into the world of data center storage solutions, and she has been actively involved in managing data center QLC SSD products since their inception. Yuyang holds a Bachelor's and Master's degree in Electrical Engineering from University of British Columbia and an MBA from the Wharton School of Business. In her leisure time, she enjoys playing badminton and even co-founded a local badminton club with hundreds of active members.